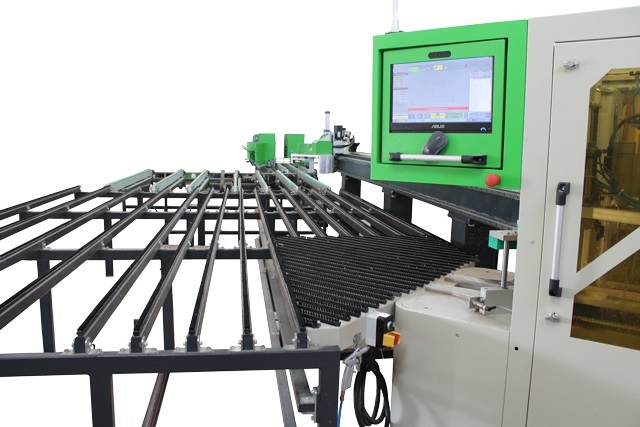

WFOUR CORNER HEAD WELDİNG AND CNC CORNER CLEANİNG LİNE 8000

· It is designed for 90 ⁰ welding and cleaning of pvc profile frames as a line.

· Line has 4 different stations ; welding station ( RY-4050 ) , cooling station (CNC-6006C ) , transportation-turning station ( CNC-6006T ) and cleaning station ( CNC-6006 )

· Ability of zero welding (0,2 mm) for colored profiles

· Pc controlled with Windows operating system.

· Easy and fast data transfer because of Pc ( by usb memory , cable , cd , wireless, Ethernet , mail etc. )

· New profile programs that have been sent by e-mail can be easily downloaded to software of machine without any need to technical stuff.

· Thanks to 19’’ lcd control screen for being user-friendly

· Remote control service technology.

· Because of barcode reader system welding heads move to dimensions automatically.

· Manual or automatic working ability.

· It has automatic profile recognition system. Because of this, no need to make selection for profiles by the operator.

· Unlimited profile system data memory.

· Automatic lubricating system.

· Production capacity is 200-240 frames/8 hours.